I recently took up 3D printing as a hobby, since designing and creating items to use around the house seemed like an extremely cool idea to me. As a result, I’ve made accessories for my home office, upcycled broken furniture by printing replacement parts, and even printed last-minute gifts for friends when I’ve forgotten important occasions. Essentially, getting a 3D printer has made my life easier in a lot of ways. However, I faced several challenges when I initially got the printer home. Right from assembling the rails to leveling the bed, the experience was anything but rosy. Let’s just say I expected things to be a lot smoother.

Apart from these teething issues, there are several other factors that I wish I had known before dipping my toes into the world of 3D printing. Not only would it have allowed me to ease into the process of creating my first 3D print, but it would also have helped me pick the right 3D printer for my usage and requirements. Well, I used this experience to put together a list of things I wish I had known before getting my first 3D printer. If you’re saving up for your first 3D printer, you can also use this as a guide for the parameters to consider when picking a printer.

Related

5 ways I save money with my 3D printer

There are so many things I don’t have to buy anymore

5

Which type of printer to buy

FDM or SLA?

3D printers are broadly classified into two types – Fused Deposition Modeling (FDM) and Stereolithography (SLA). FDM printers are more popular as they are more affordable and generally well-suited for beginners. This is because they employ filaments that melt to form objects based on the shape of the model. If you’re trying to introduce 3D printing to your kids, this is the way to go. SLA printers, on the other hand, are more sophisticated and offer better details when printing objects like figurines, replicas of popular structures, etc. However, they use resins instead of filaments.

As a result, they are more difficult to handle and operate, and can often get messy if you have no prior experience working with resins. I would recommend opting for an FDM printer for your first printer and then upgrading to an SLA one later on. Initially, I decided to buy an SLA printer after reading that the prints are more detailed. But I’m glad I went with an FDA printer since it’s much easier to use.

4

Ensure compatibility with all materials

Print with ABS and TPU as well

FDA printers use filaments of various materials. There’s PLA, PETG, ABS, TPU, etc. PLA is the most popular one since it is universally used for most types of prints, and it’s also the most affordable one. However, PLA is heat-resistant only to a certain extent, and it’s also rather brittle. So, you may want to use materials like ABS for a stronger build. Moreover, if you’re printing items to store food or groceries, you will have to use food-safe ABS.

So, you need to make sure the printer you’re getting can support printing in all the different materials. There are several factors that determine this. Every material has a certain temperature at which it melts, so the hotend needs to support those temperatures. Additionally, some materials release harmful fumes, so an enclosure is important. If you want to print softer objects, you can use TPU — but your printer needs to support it. Owing to this, I would recommend opting for a mid-range printer with an enclosure. This way, you can start with PLA or PETG and then move on to more complex filaments since your printer will be future-proof for a while.

Related

7 reasons I’m switching to PETG filament for my 3D printing

While PLA filament is best for 3D printing beginners, there are strong advantages to using PETG instead

3

Designing objects isn’t easy

Making your own objects requires effort

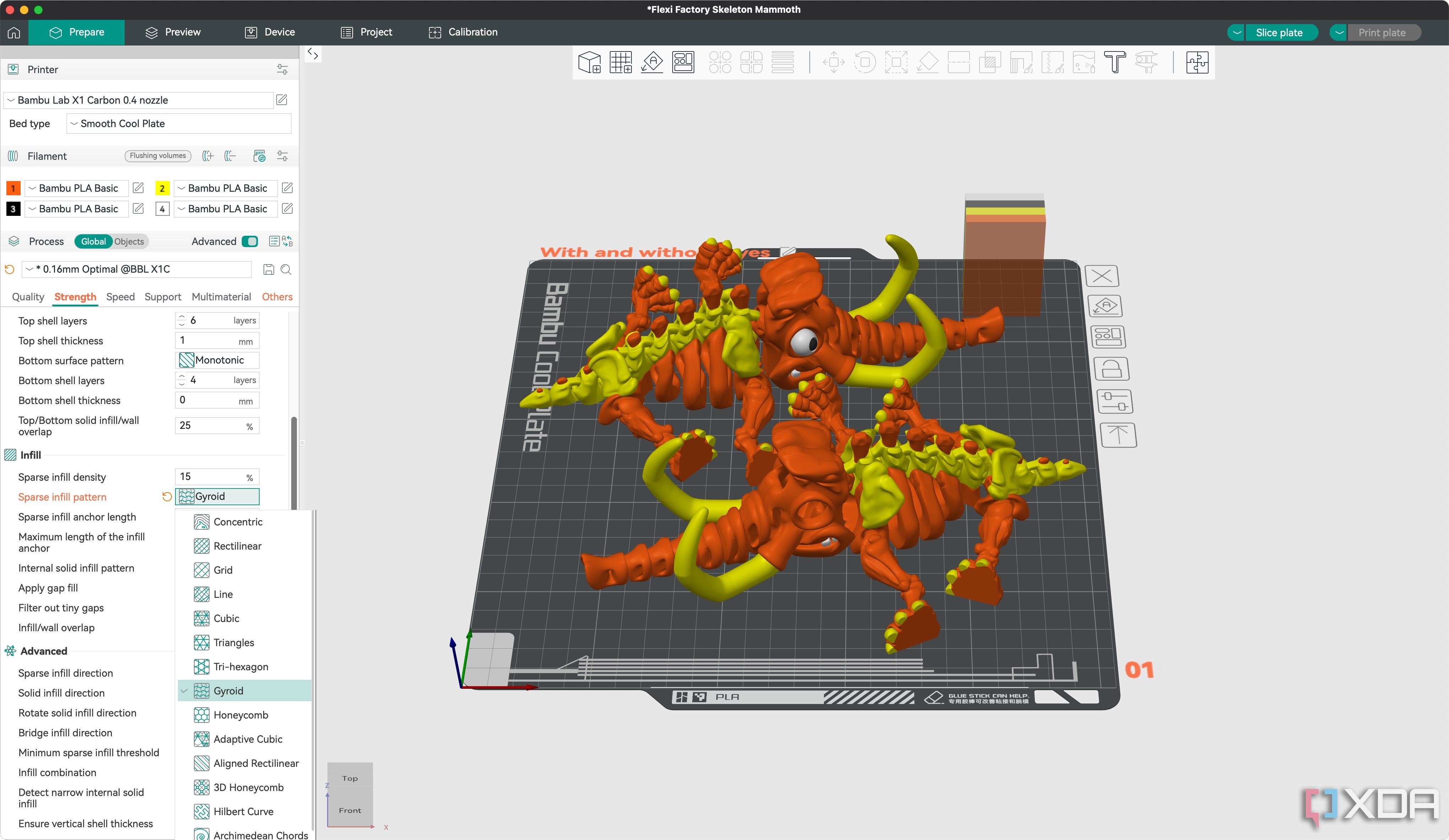

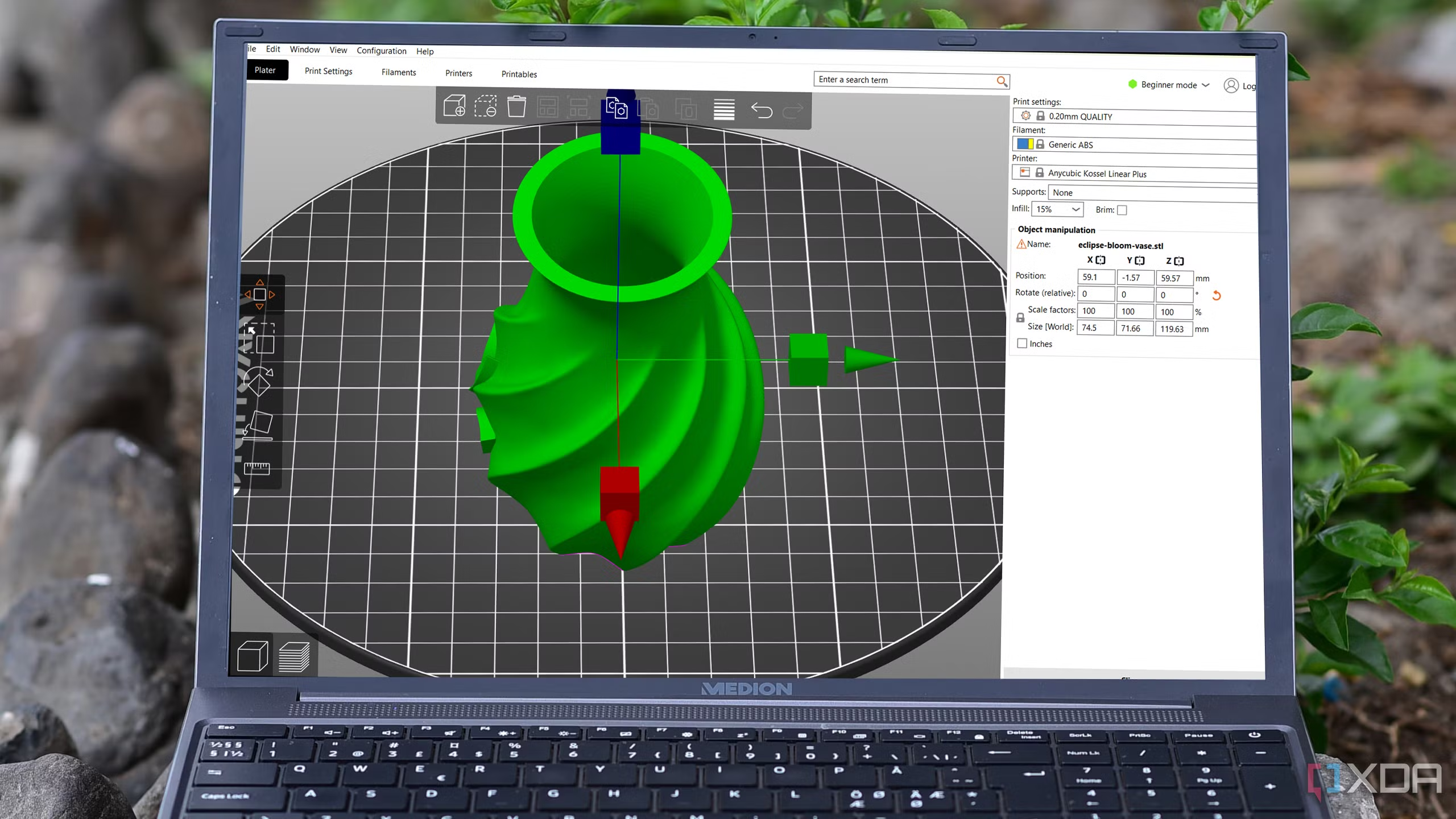

Now, there are tons of online portals and databases where you can find 3D models that you can simply download and print. These are excellent for calibrating your printer or for beginners who wish to experiment by printing various types of objects. However, if you want to go one step ahead and print exactly the type of objects you want, you will have to design them yourself using design software like Blender, Fusion 360, etc.

This is quite challenging if you have no prior experience with designing objects using a computer. There are several courses and tutorials online that you can follow, but that doesn’t ensure your designs will print just the way you want them to. You will have to make several iterations, test, change a few things, and even learn to use slicer software like Cura, Prusa, etc. All of this requires time and effort, so get ready to set aside a few hours every day to master these applications. Otherwise, you won’t be able to take full advantage of your 3D printer.

Related

5 free 3D printer slicers to try

Use these 5 free 3D printer slicers to generate the G-code to send to your 3D printer.

2

It’s not a plug-and-play device

You’re by yourself when troubleshooting

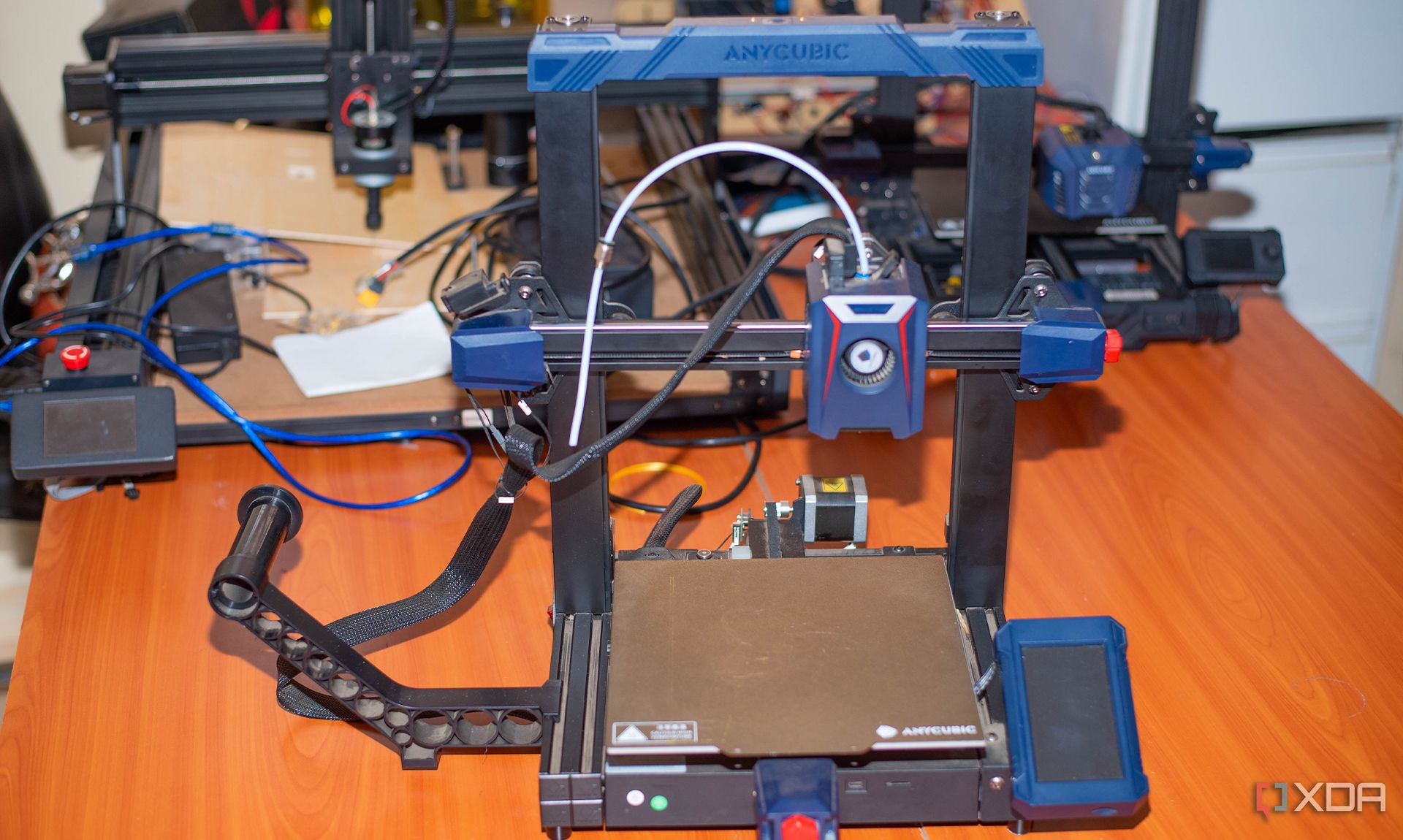

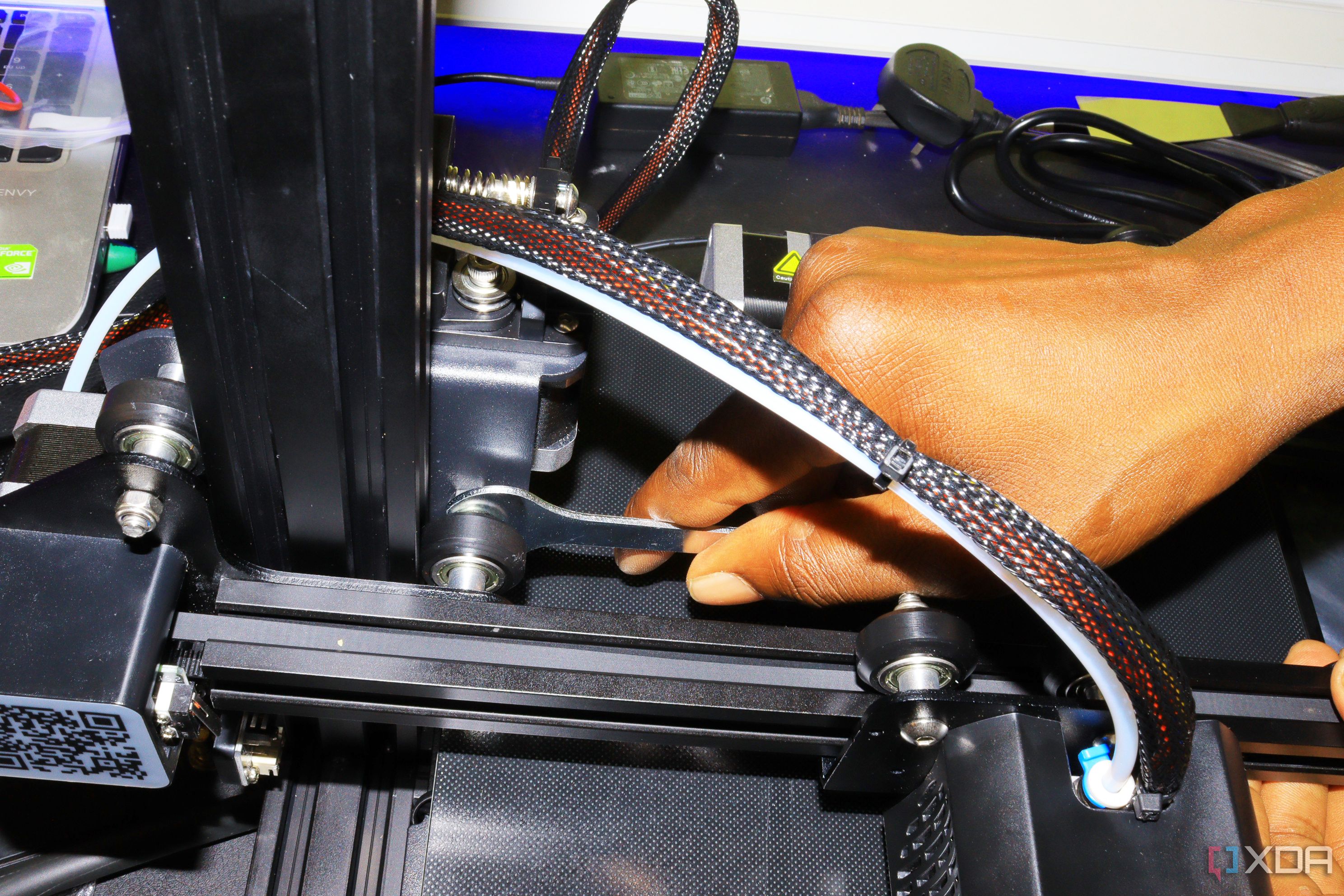

Most electronic devices and appliances nowadays are of the plug it and forget it kind. You just have to plug them in once, and they start working without a complicated setup process or manual driver installation. However, a 3D printer is far from that. Firstly, most 3D printers come in a disassembled state. You have to assemble them yourself, and while the process is mostly straightforward, if you follow the instructions, it’s not too hard to overlook small aspects that may result in issues.

Even after you’ve assembled the printer, you may face problems regularly since 3D printers have moving parts, so the vibrations and constant movement can cause wear and tear. In all such situations, you’re on your own to figure out possible solutions and fix the printer. You’ll have to research online forums, go through multiple posts and comments to see what others with the same issue have done, and even have to diagnose issues by yourself.

Related

5 reasons your 3D printer may be making weird noises

Fix the noise and your prints!

1

Prints can take forever and fail

Lots of wastage

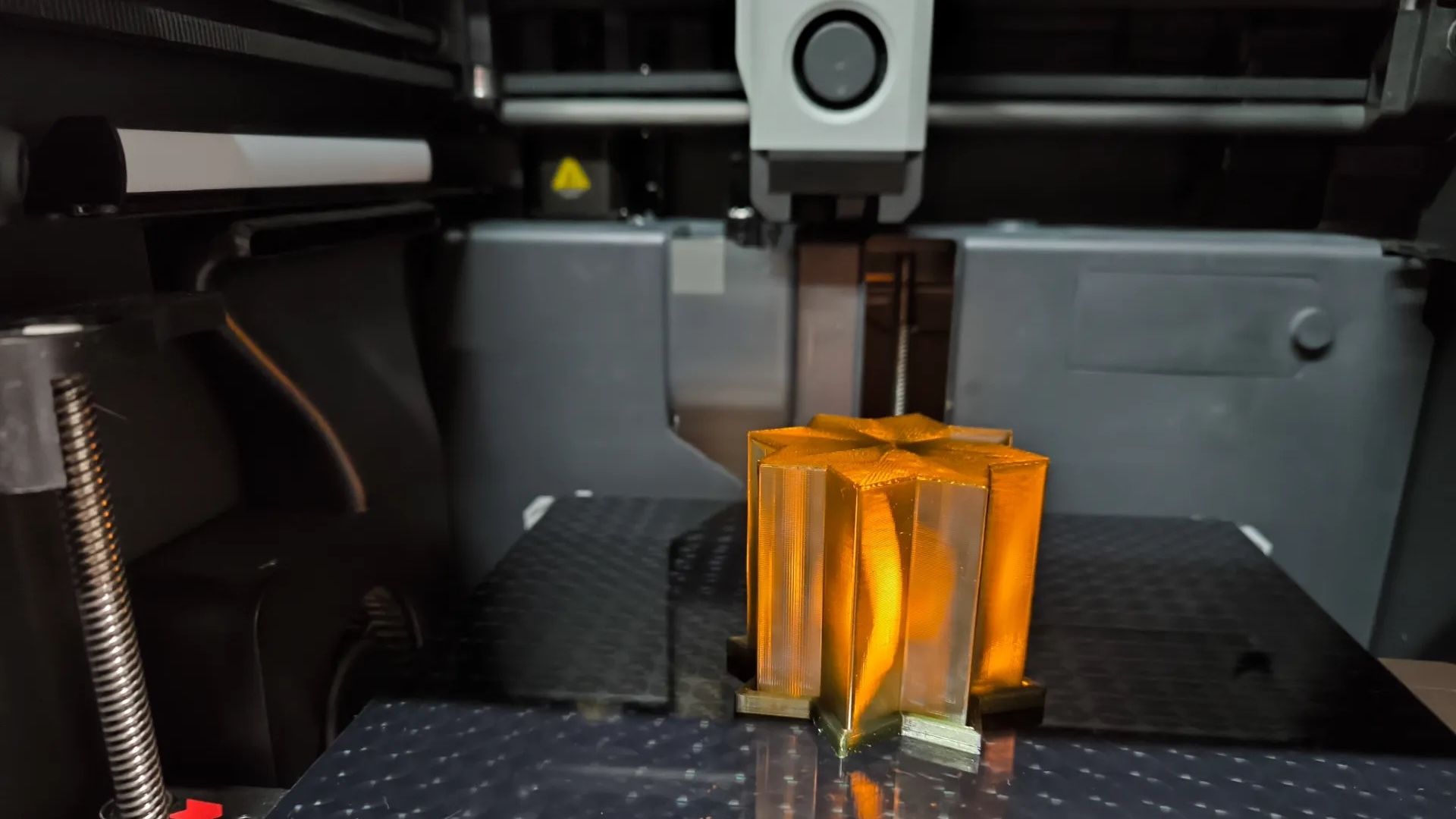

3D printing can be magical. You can print pretty much any object you want, whenever you want. However, the biggest caveat that I wasn’t aware of before I got into the world of 3D printing is that printing items takes time. A lot of time. As the size of the objects keeps increasing, the time also increases substantially. Now, this also depends on the printer you have, but in general, be prepared to wait for a few hours for a normal-sized print.

For example, I printed a small cable holder for my desk, and it took an hour to print. A wallet that I printed to house six credit cards took five hours to print. It was my friend’s birthday, and he’s a massive Batman fan. So, I printed him a Batman figurine about six inches tall, and it took 17 hours to finish. Yes, 17 hours. What’s worse is that the print failed twice, first around the three-hour mark and then, around the seven-hour mark. So that’s a total of 27 hours spent on a single print. The failed prints also lead to filament wastage, and they certainly test your patience.

Related

7 issues I faced while 3D printing as a beginner and how I fixed them

Don’t let failed prints deter you

Make the right choice

Unlike most tech gadgets or appliances, 3D printers have a lot of nuances that need to be understood before you spend your hard-earned money. That’s what I realized after buying a printer in haste. I wish I had first figured out what type of prints I would be making, how fast I wanted the prints to complete, and how spending slightly more would have gotten me a much better printer with fewer quirks.

Related

I 3D printed my own keycaps, and now I’m addicted

Customize your keyboard right at home