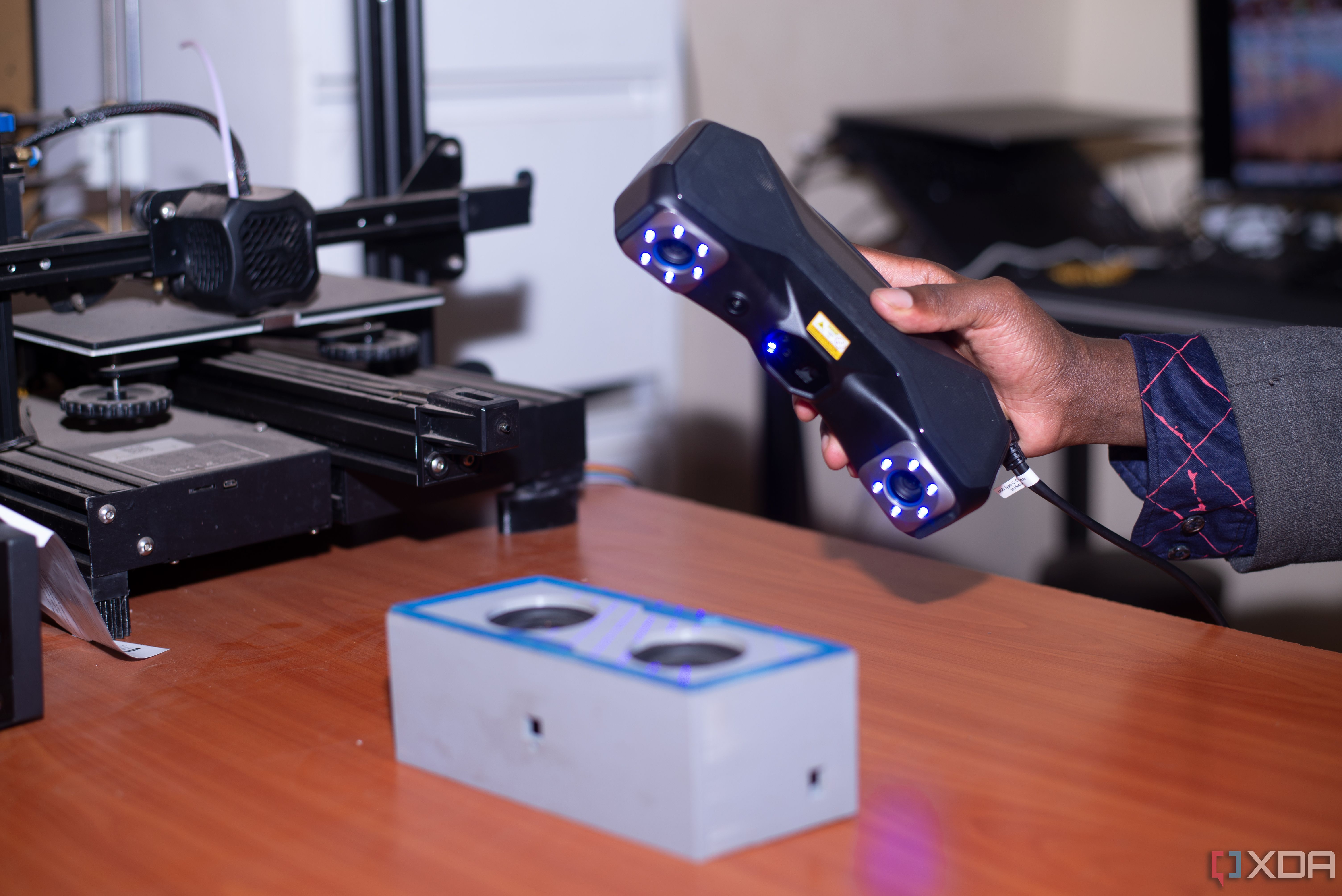

I have been 3D printing for a while now, and throughout, I have created my files for 3D printing using a 3D modeling program, as well as occasionally downloading them from 3D printing websites. It wasn’t until recently that I acquired a MetroX 3D scanner to explore a new method for generating files for existing parts, then 3D printing them. Just like any other skill, mastering 3D scanning comes with its own learning curve. It wasn’t just about holding the scanner and moving it around the part or design to create a digital file. It’s more than that. I have learned valuable lessons since acquiring the scanner, which I wish I had known before getting started, and I have shared them below.

Related

5 Interesting applications of 3D scanning

These five remarkable applications of 3D scanning demonstrate the vast potential of the technology across various fields. Check them out.

5

Consider the size of the objects before buying a 3D scanner

3D scanners have a limited range

Before purchasing a 3D scanner, consider the size of the objects you plan to scan. Not all scanners are created to handle objects of all sizes; each has a minimum and maximum distance at which it can accurately capture details. Some are designed to handle small, intricate models well, while others are better suited for scanning larger items.

If you try to scan something too small with a scanner designed for larger items, you’ll probably lose a lot of details. On the other hand, if you scan a large object with a small-range scanner, it will require dozens of separate scans, which are then stitched together to form a complete image. This process can be time-consuming and messy at times. When considering the objects you will be 3D scanning, it will help you select one with a range and resolution that fits your project, and this will save you a lot of frustration along the way.

4

Have a high-end computer

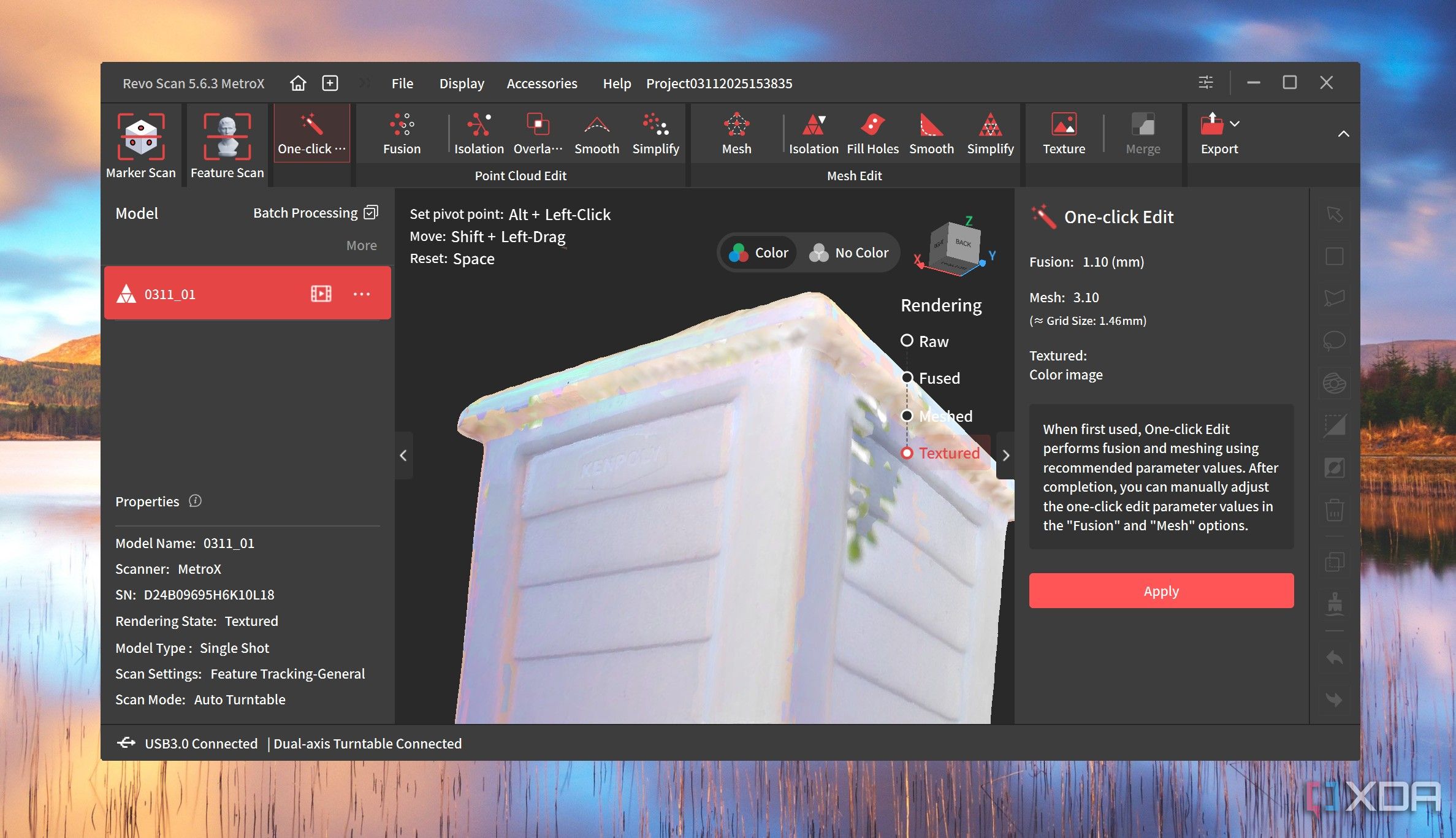

The 3D scans can have huge file sizes and complex

3D scans can be massive, especially when capturing high-resolution details, as they involve meshes with millions of polygons. If your computer can’t keep up, especially during 3D scanning or editing the scans, it will lag significantly. I recall that before acquiring the MetroX scanner; I saw the recommended PC requirements were an Intel i9 12th Gen processor, at least 64GB of RAM, and an RTX 4060 or better GPU. I didn’t have such a model, but I had to upgrade my PC to fit, and when I received it, it ran smoothly. However, when I tried to run it on my other PC to see how it performs with lower specs, it lagged.

Additionally, most of the recommended software that comes with 3D scanners often requires powerful machines. If you try to run it on minimum specifications, you might find that the software won’t run at all, or it will run slowly. Therefore, if you want to scan and edit files smoothly without issues, you need a powerful machine. If you are considering using a smartphone scanner app for scanning, an iPhone (iPhone 12 Pro and up) is more recommended than an Android because it has a built-in LiDAR sensor, which provides the iPhone with an accurate way to measure depth and distance in real-time. This makes scanning reliable and detailed, even in lower light conditions. Android phones mostly rely on a regular camera, which isn’t very precise.

Related

3 Reasons why I use Metrox 3D Scanner to create detailed 3D models for 3D printing

MetroX is a powerful 3D scanner that can help you capture 3D scans of objects and even clean them up. Get to know the main reasons why I like it.

3

Scanning is only half the job

You have to edit and clean the scans

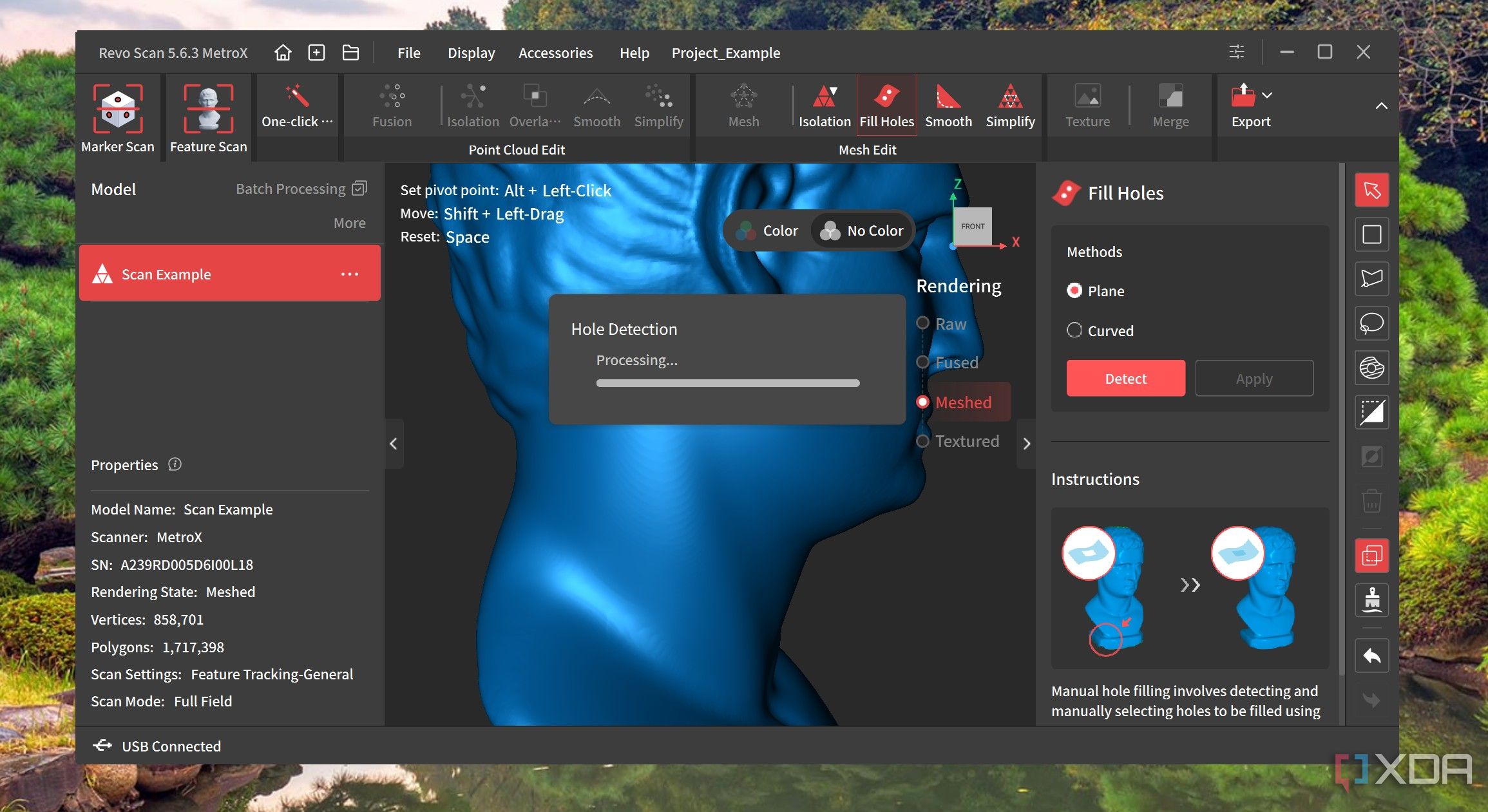

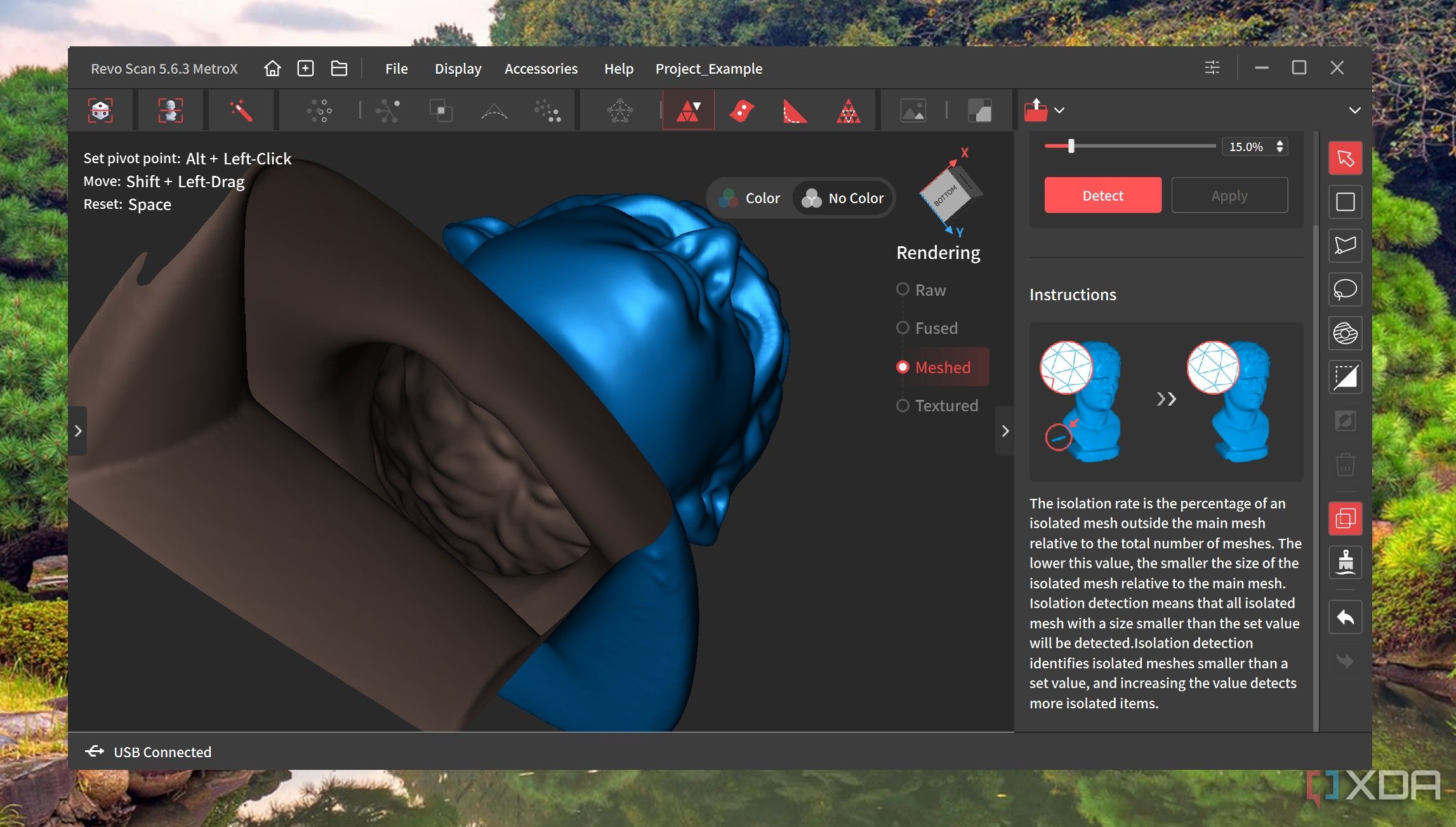

Once you have captured the scans, you need to edit and clean them. Raw scans almost always come with imperfections, and the scanner might have captured unwanted parts that need to be removed. Even with a high-quality scanner, the data you obtain isn’t ready for use, especially if you plan to 3D print, animate, or integrate it into a larger design project.

Editing the scans involves filling in holes and smoothing out rough areas. Sometimes, you also need to reduce the polygon count to make the file easier to handle or to ensure compatibility with other software. If the file is to be 3D printed, ensure it is watertight to avoid common 3D printing problems, as 3D printers cannot work with broken geometry.

2

The environment and lighting matter

Ensure the surroundings are clean and properly lit

An overly busy background can confuse the scanner, especially if it’s relying on photogrammetry or structured light. Ideally, you want a clean, neutral backdrop that allows the scanner to focus entirely on the object. If you’re using a turntable setup, placing a solid-colored cloth behind the object can help isolate it visually and improve the scanner’s accuracy. Moreover, proper lighting is essential. If it’s uneven, it can create harsh shadows or bright reflections, which can interfere with the scanner’s ability to capture surface details. You can use a ring light or softboxes to provide consistent illumination that helps the scanner read depth and texture accurately.

Related

Galaxy Note 10 3D Scanner app is here along with Samsung’s Discord integration

Samsung announced that Galaxy phones will have exclusive Discord integration and that the Galaxy Note 10 will have a 3D scanner app. Both are now live.

1

3D scanning shiny surfaces is challenging

You have to spray to get the best results

Shiny or transparent surfaces can be challenging to scan at times because they reflect light, which can interfere with the scanner’s ability to capture accurate details. Some scanners capture these well; however, others may struggle a bit. To overcome this, you must first adjust the settings on the scanner or the software. Some scanners are good at adapting to surface variations or object types. You can adjust the exposure settings to compensate for the objects’ surface.

If the software of the scanner that you are using allows you to change the object, you can do so. For example, the MetroX 3D scanner offers the option to choose the type of object being scanned. If you adjust the settings and still cannot capture the object well, you may need to apply a scanning spray or a matte opaque coating to cover the surface, preventing issues during scanning.

3D scanning is an interesting technology

A 3D scanner, just like any other tool, takes time to master. When I first got mine, I had no prior experience using one, so everything was new to me. I went through a lot of trial and error, in addition to reading documentation and watching videos. When I look back, there are a few things I wish I had known before purchasing a 3D scanner, and the five listed here are the most significant ones. If you’re just getting started, don’t be discouraged; the learning curve is real, but so are the rewards. Once you get the hang of it, you will be able to capture any real object and turn it into a 3D model with ease.